Â

Â

|

Model |

5+1 Axis CNC bridge saw |

Unit |

|

Worktable size |

L3500*W2000 |

mm |

|

Maximum cutting |

L3500*W2000*H90 |

mm |

|

Maximum chamfering |

L3500*W2000*H60 |

mm |

|

Blade diameter |

350-425 |

mm |

|

Main motor power |

22 (permanet magnet motor with frequency) |

kw |

|

Router power |

5.5 |

kw |

|

Control center |

industry computer with CNC |

|

|

Controller brand |

own CNC system or ESA system from Italy |

|

|

Driving motor |

Servo motor |

|

|

Router max speed |

24000 |

RPM |

|

Total power |

35 |

kw |

|

Suction cup lifting weight |

200 |

kg |

|

Head rotate |

0°-360° |

|

|

Head tilt |

0°-90° |

|

|

Cylinders |

5 |

group |

|

Dimensions |

L5750*W3260*H3800 |

mm |

|

Water consumption |

2 |

m³/h |

|

Total weight |

5.4 |

t |

|

Main part delivered size |

5750x2200x2500 |

mm |

|

Machine-delivered method |

Main part delivered as a whole (HQÂ container) |

|

Â

Price|

Model |

Own system (USD) |

Option: ESA System |

Option: Hot Galvanized (USD) |

Option: front sliding doors |

Option:worktable with plastic plate and rubber |

|

ZLBS-425CNC/5A |

31000 |

+5000 |

+2000 |

+2000 |

+1000 |

Â

Â

1: The machine is a conjoined structure; it takes up less space and is easy to install and move.

Â

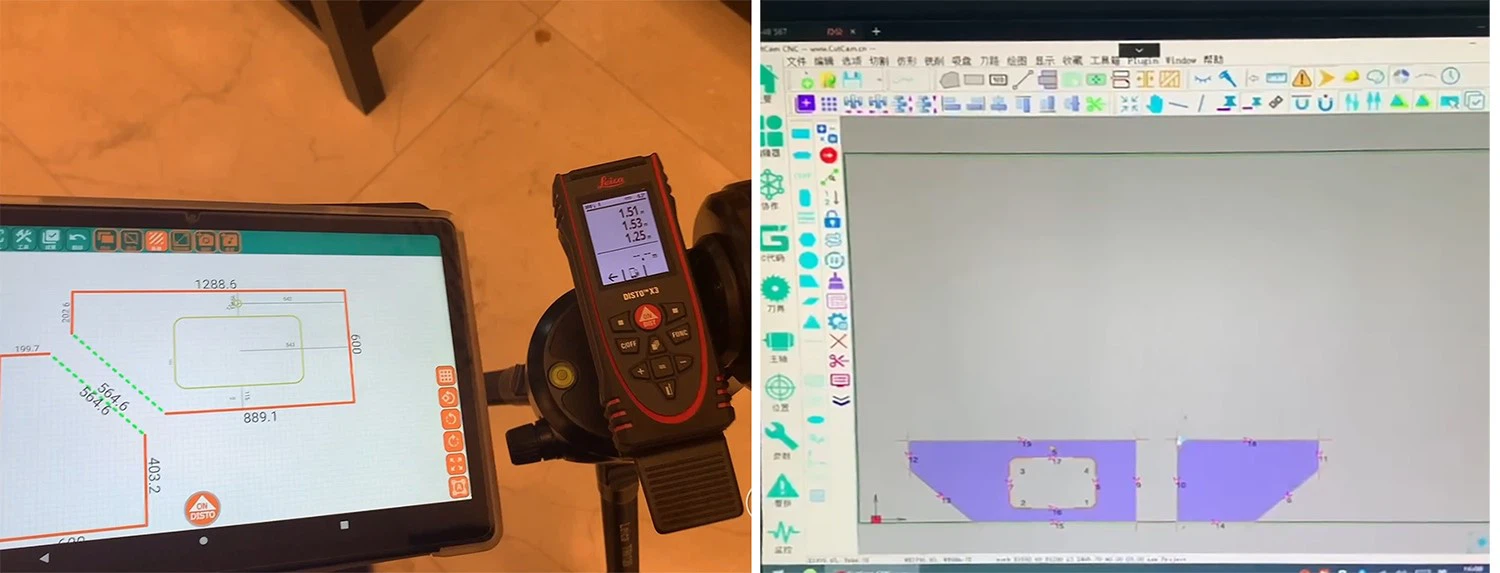

2. The system has a built-in library of conventional-shaped drawings and also supports DXF format imports from a designer or a countertop measuring gauge. With an industrial computer and a 17" color touch-screen.

Â

Option: own CNC system or ESA system from Italy

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

3: Use a camera to locate the position of the plate and display it in the cutting procedure.

Â

Â

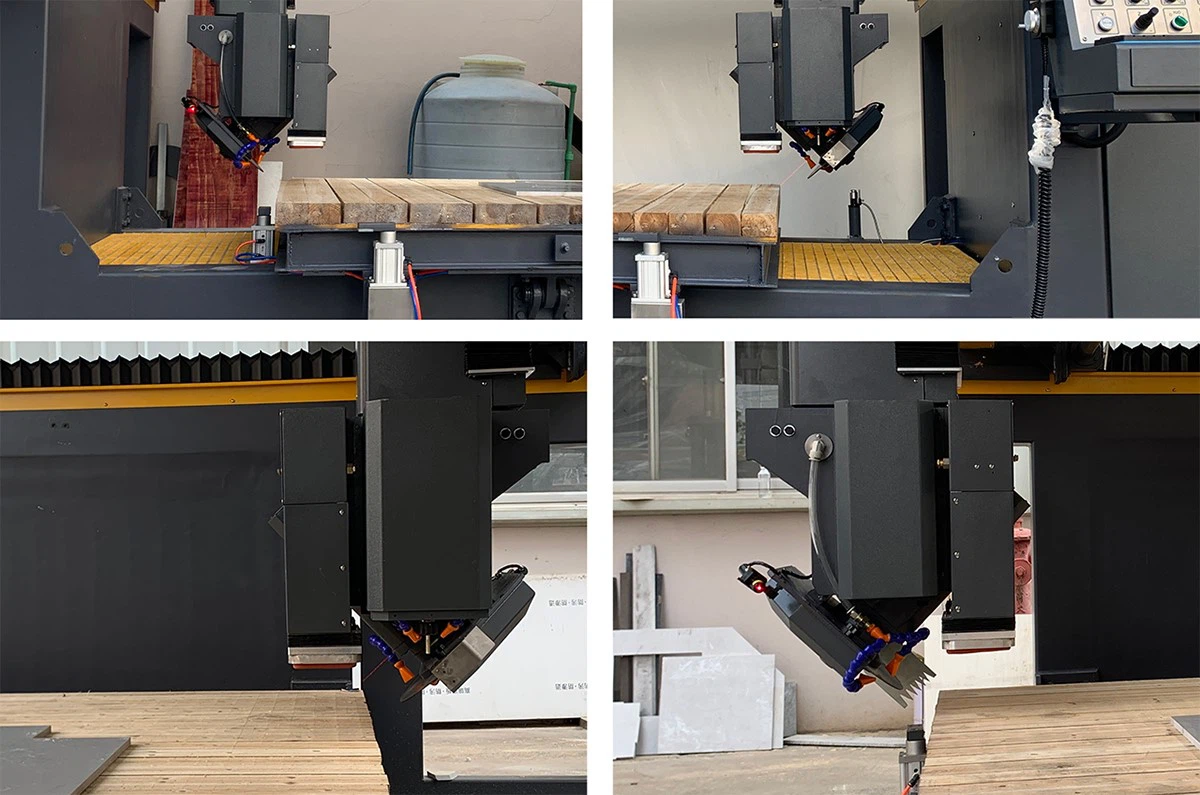

4: This machine has excellent four-side chamfering function and an excellent chamfering range 3500x2000mm

Â

Â

5: The (5+1)A type with a 22-KW permanent magnet motor can be cut along with the thickness of the cutting plate, automatically adjusting the output power, strength, and power-saving environmental protection.

6: An automatic tool setting gauge is equipped that automatically checks the blade.

Â

7: A group of rotating cylinders on the side of the work table will automatically press the plate when the milling cutter works and automatically withdraw after the milling cutter works.

Â

Â

Â

8: The worktable can be flipped up to 85°.

Option: the machine chassis could be hot-dip galvanized, and the worktable could be faced with plastic plates and rubber.

Â

Â

Â

Â

9: Option: front sliding doorÂ

Â

Â

Â

Â

Â

Â

Â

Â

Â

Â

5+1 Axis CNC bridge saw is an easy machine. It can cut conventional cross and straight slices of plates; the operator can also process various forms of chamfering and 3D shaping, such as arc line shaping and chamfering, wave line shaping and chamfering, and cut various polygons, circles, ovals, maws, L-shaped countertops, four-sided under-hung countertops, etc. The router can mill various kinds of holes and inner angles. 5+1 Axis CNC bridge standard configuration of 22KW permanent magnet motor can be cut at high speed and save energy. It supports downloading the file from the measuring instrument, then setting the drawing on the photo and starting. So the machine is good at achieving dust-free installation of countertops.For each machine, we place the stone test machine in the factory to ensure that every detail is debugged to the best state and then package the factory. The main engine part and the circuit part are the same when loading containers, so it is very easy to install and debug the machine in the customer factory. And we provide distance teaching and troubleshooting services.

Â

5+1 Axis Bridge Saw – The Ultimate Stone Cutting Solution

The 5+1 Axis Bridge Saw is an innovative stone cutting solution that takes precision and accuracy to the next level. Equipped with state-of-the-art technology and advanced features, this machine has revolutionized the stone cutting industry. In this article, we highlight the top 5 advantages of the 5+1 Axis Bridge Saw and some positive customer feedback.

1. Superior Accuracy and Precision

The 5+1 Axis Bridge Saw is equipped with advanced sensors and controllers that enable it to cut stone with unparalleled accuracy and precision. The machine’s automated cutting process ensures that each cut is uniform, straight, and clean. This level of precision ensures that the overall quality of the stone is higher, and the end product looks more appealing.

Positive Feedback: "We were blown away by the accuracy and precision of the 5+1 Axis Bridge Saw. The cuts were clean, and the edges were smooth. This machine has exceeded our expectations."

2. Increased Efficiency and Productivity

With its advanced automation and user-friendly interface, the 5+1 Axis Bridge Saw can quickly and effortlessly cut through large quantities of stone. This efficiency means that customers can get their products faster, and businesses can increase their productivity and output.

Positive Feedback: "The 5+1 Axis Bridge Saw has been a game-changer for our business. We can now cut more stone in less time, which means we can take on more orders and increase our profits."

3. Reduced Waste and Material Loss

The 5+1 Axis Bridge Saw's advanced cutting technology allows for precise cuts, which means there is less wastage of material. The machine can also optimize the layout of the stone, which means it can use more of the raw material, reducing overall wastage.

Positive Feedback: "We've noticed a significant reduction in material wastage since we started using the 5+1 Axis Bridge Saw. It's optimized our layouts, and the cuts are so precise that we're using less material overall."

4. Suitable for Variety of Stone Types

The 5+1 Axis Bridge Saw is versatile and can cut through a wide variety of stone types, including granite, marble, and engineered stone. With its advanced technology, the machine can handle even the most challenging stone types.

Positive Feedback: "We've been using the 5+1 Axis Bridge Saw on a variety of stone types, and it has handled them all with ease. It's a versatile machine that can handle anything we throw at it."

5. Ease of Use and Maintenance

The 5+1 Axis Bridge Saw is designed with the user in mind. It's a user-friendly machine that is easy to operate, clean, and maintain. This ease of use reduces the risks of downtime and ensures that the machine is always in excellent working condition.

Positive Feedback: "The 5+1 Axis Bridge Saw is effortless to use and maintain. The routine maintenance is simple, and we've had no issues with downtime since we started using it."

Conclusion

The 5+1 Axis Bridge Saw is an innovative machine that has transformed the stone cutting industry. Its superior accuracy and precision, increased efficiency and productivity, reduced waste and material loss, versatility, and ease of use and maintenance have made it a popular choice for businesses and customers alike. Positive feedback from satisfied customers has validated these benefits and shown that the 5+1 Axis Bridge Saw is a valuable investment for any stone cutting business.

http://www.zlstonemachine.com/